Shoe Development

Escalons sole

The sole is the centerpiece of the model.

Introducing the Escalons sole. Born from the Escalons signature language of Rebel Bomb.

Inspired by the word 'escalones,' which originates from the Latin word scāla, meaning 'stair.' The concept embodies the idea of individual steps that elevate both style and functionality.

Parallel lines on different levels provide balance, definition, and volume to the shoe's sole.

Upper Part

Crafted from a single piece of full-grain leather, the upper embraces the foot like a glove, elegantly aligning with the bold, saturated sole.

The Rebel Bomb logo is positioned on the sole’s bottom and lateral sides, as well as on the tongue and heel tab of the shoe.

The Escalons sole design is internationally patented.

Materials

At Rebel Bomb, we meticulously select top-notch materials from the best suppliers in the market.

Our soles are crafted from pure virgin rubber, free of artificial additives, using a traditional vulcanization process. The complexity of the Escalons design makes our soles four times more challenging to produce than a regular shoe sole. In the final stage of fabrication, excess rubber is carefully removed by hand using a special tool called a mototool.

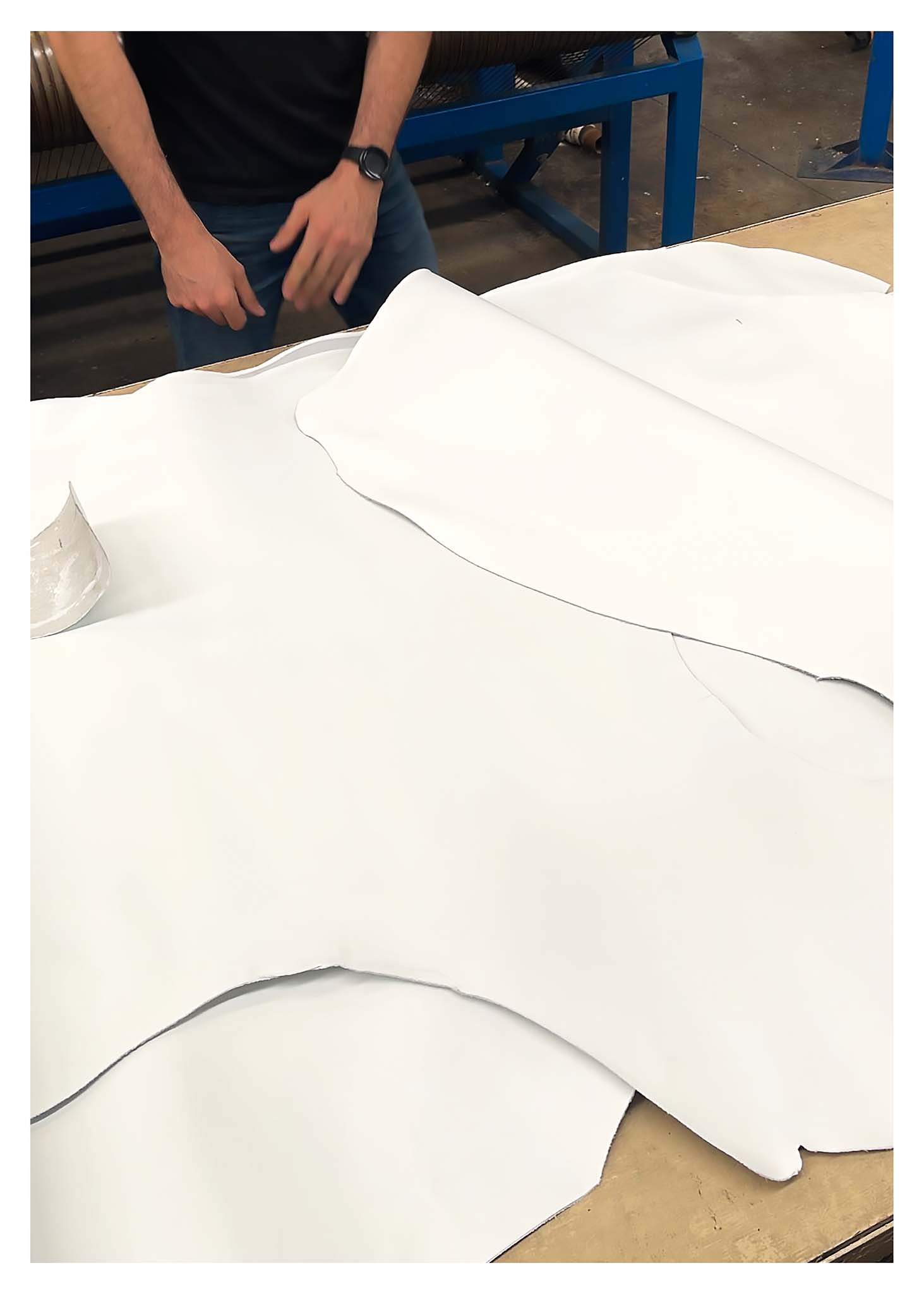

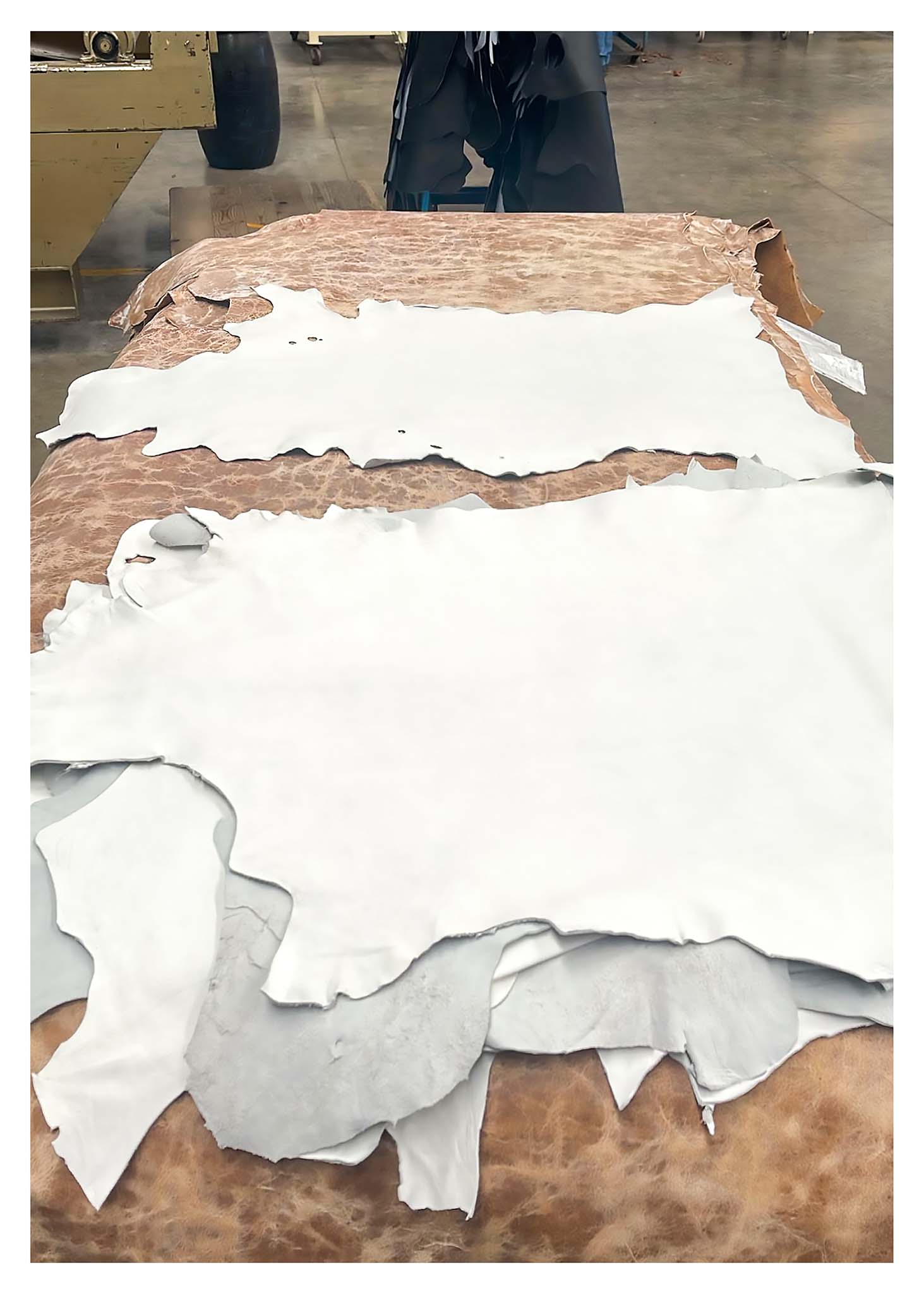

The leather we use is a full-grain, first-selection leather, considered the pinnacle for everyday leather goods. Each shoe features a single cut of full-grain leather, maximizing both quality and comfort.

For the lining, we opt for calfskin leather, known for its exceptional smoothness, providing a sophisticated feel with every wear.

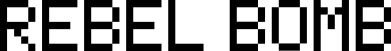

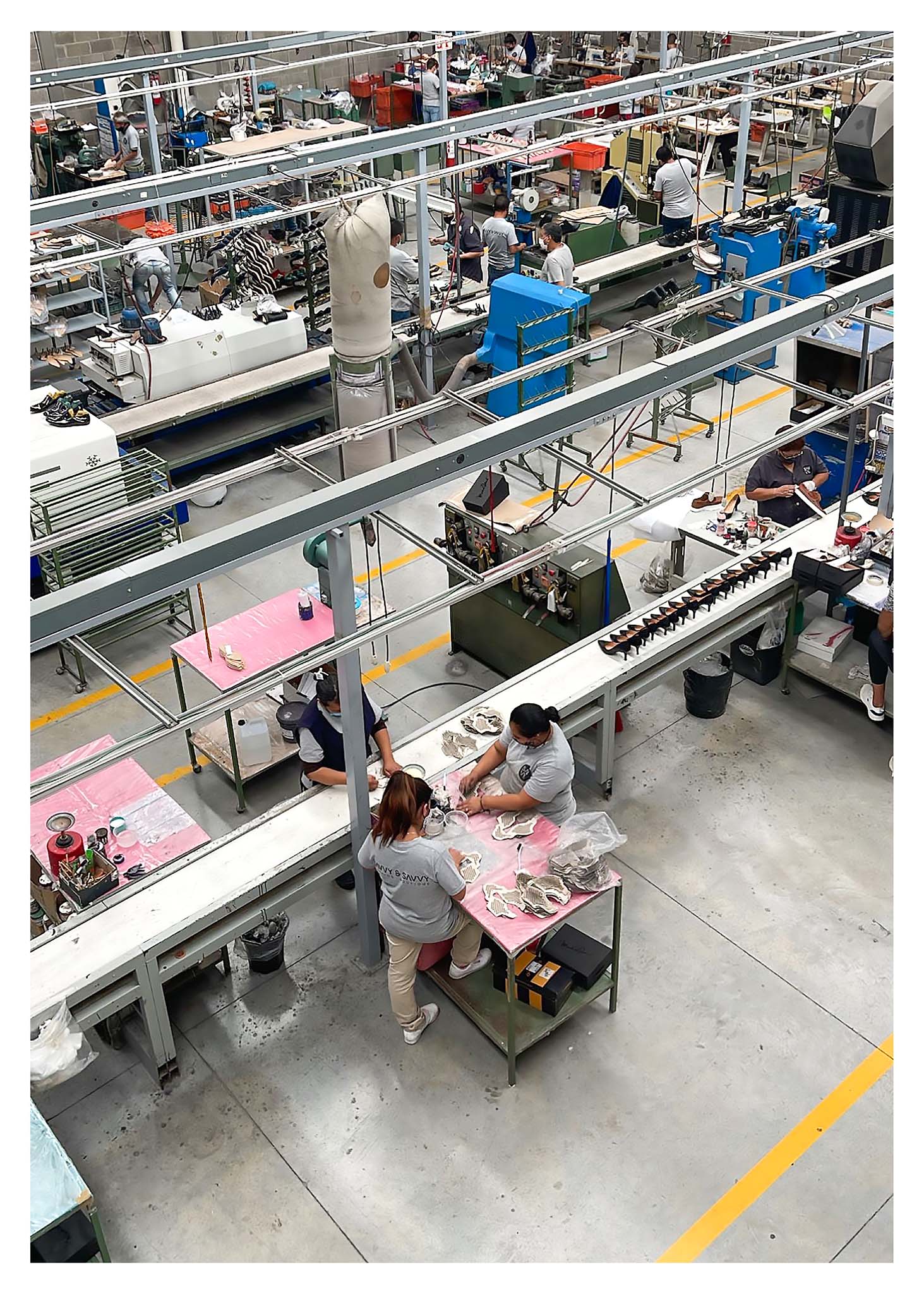

Artisanal Craftsmanship

Finding the right factory was one of our biggest challenges. After meeting with over fifteen factories, we finally discovered a small atelier of artisans who embody the old-school shoe craftsmanship we sought for this project.

A key factor in our successful partnership with the factory is their genuine belief in our vision and their investment in the project. This shared commitment ensures that every pair of shoes meets our high standards and reflects the passion we put into our work.

Prototypes

The development process involved nine prototypes over the course of four years to arrive at the final product.

Prototype #1: 10/10/2021

Prototype #2: 09/12/2021

Prototype #3: 13/02/2022

Prototype #4: 07/05/2022

Prototype #5: 19/07/2022

Prototype #6: 26/08/2022

Prototype #7: 07/07/2023

Prototype #8: 24/11/2023

Prototype #9: 13/07/2024 (final product)

Sole Design Patents

USA: U.S. Patent App. No. 29/792,841: SHOE SOLE (222203620.SALD)

Mexico and Latin America: MX/f/2021/003449

Europe and Asia: In process

Documents from the Historical Archives of León, Guanajuato, indicate that the production of leather goods and footwear began in the city during the 16th century.

The shoe development took place across three different factories.

We initially worked with a factory producing 3,000 pairs per day, then moved to a smaller one that produced 3,000 pairs per month. Neither had the craftsmanship or attention to detail our project required.

Over the course of 8 months, we engaged with more than 15 shoe factories, and finally discovered a small atelier of artisans who embodied the old-school shoe craftsmanship we had been seeking for this project.

“La rebaba” refers to the excess of rubber remaining from the vulcanization process of the sole.

Removing la rebaba is the most challenging aspect of the sole fabrication due to the design of Escalons.

"La horma" is considered the soul of the shoe.

We made over 30 modifications to it, testing different materials to achieve the ideal shape and fit.

We selected full-grain leather, Bomba Blanca, for our model due to its superior quality, concept, and comfort.

The lining, crafted from premium calfskin leather, is regarded as one of the most essential materials of a shoe, as it comes into direct contact with the foot.